AWARD YEAR

2021

CATEGORY

Community

GOALS

Industry, Innovation & Infrastructure, Sustainable Cities & Communities, Responsible Consumption & Production, Climate Action

KEYWORDS

sustainable building materials, CO2

COUNTRY

United States of America

DESIGNED BY

Solidia

WEBSITE

https://www.solidiatech.com/

Solidia - sustainable cement production

Solidia makes it easy and profitable to use CO2 to create superior, sustainable building materials.

When it comes to climate change, cement production is a major culprit, accounting for about 7 percent of the world's greenhouse gas emissions. New Jersey-based Solidia uses a patented process to address this problem, replacing limestone with a synthetic material that requires lower temperatures and less energy than traditional methods. The cement absorbs CO2 as it hardens, all of which amounts to a production process with a 70 percent smaller carbon footprint. Solidia launched commercially in the U.S. in August 2019 through a partnership with paving company EP Henry.

Solidia provides two core technologies:

1) A sustainable cement manufacturing technology, which can be produced in traditional cement kilns using less energy, reducing greenhouse gas emissions during manufacture by 30-40%

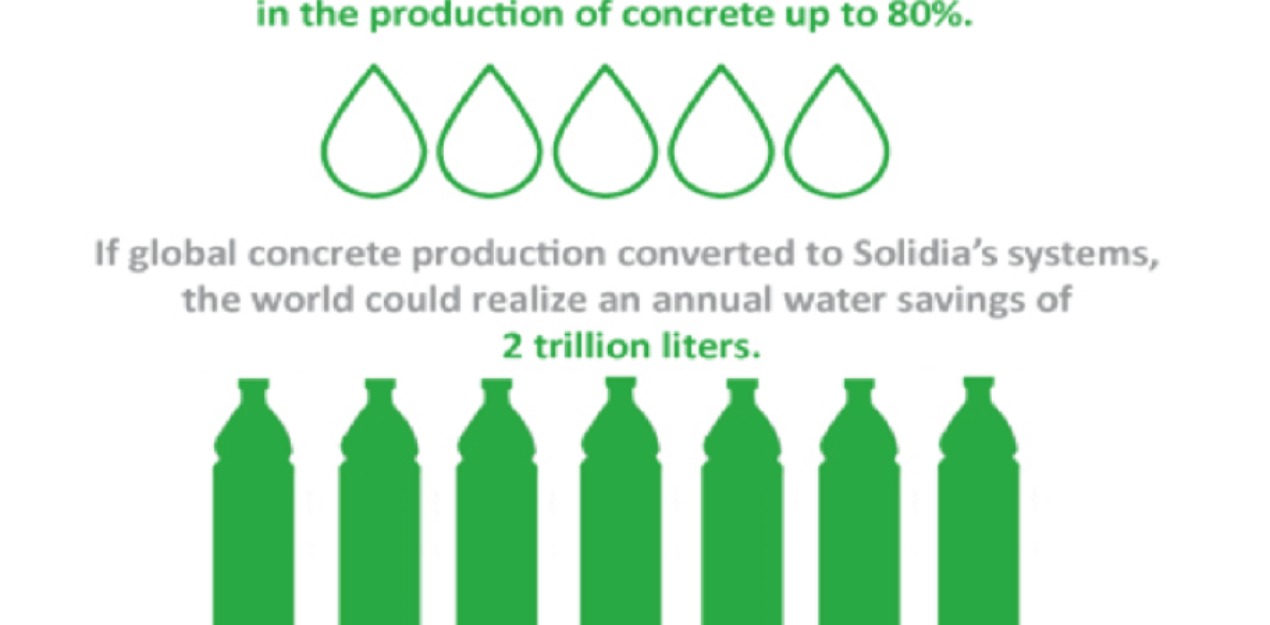

2) A sustainable concrete curing technology, curing concrete with CO2 instead of water, permanently and safely consuming 240 kg of CO2, and potentially saving 3 trillion liters of fresh water every year