Functionality and use of design

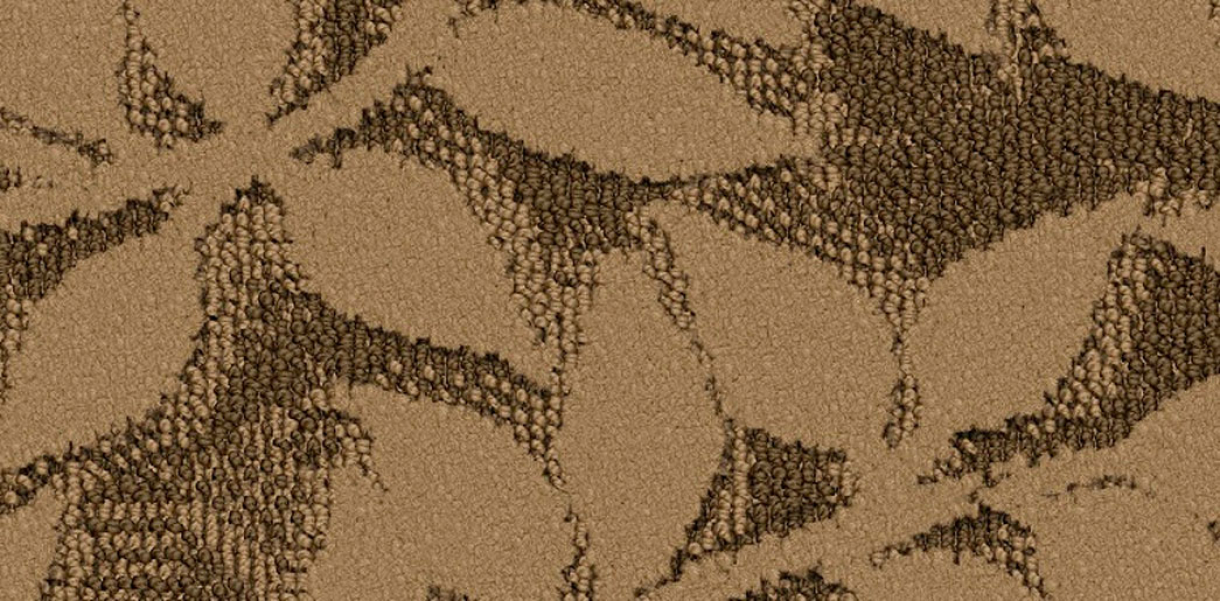

SIM samples are so color-accurate and realistically textured that they disappear when placed on an actual piece of carpet with the same pattern.

How did this design improve life?

Last year, in the United States alone 4.8 billion pounds of carpet went into landfills. Also, US $1 billion was spent by carpet and flooring manufacturers to produce carpet and flooring samples—products that are used only briefly, then thrown away.

Manufacturers have proposed alternatives to samples for twenty years (e.g. digital photography and prints from computer aided design software). But these alternatives have been rejected by their customers (architects and interior designers), because they do not show colors or texture accurately. In 2003, only 6% of architects and designers said that photography is an accurate representation of carpet, and only 6% trust prints from computer aided design software (source: Tricycle NeoCon survey 2003).

Tricycle, Inc. has developed an alternative sample that exponentially reduces the amount of natural resources and energy required to produce a sample, and is 100% recyclable. It also cuts materials and shipping costs, lessens the amount of time to market, and reduces environmental damage caused by the carpet industry. It has been accepted by the very customers who rejected previous attempts at alternative sampling.

Tricycle’s samples are digitally tufted carpet, created from combined design information, manufacturing machine data and yarn color. The samples can be viewed online or as paper prints, perfectly color-accurate and fully textured, looking just like physically manufactured carpet. Architects and designers have awarded SIM with two NeoCon Gold Awards and an International Interior Design Association Creative Excellence Award. 94% said that they would like to use SIM in their product selection process, and 74% said that SIM is the only acceptable alternative to physical samples (source: Tricycle NeoCon survey 2003).

SIM is accessible to any manufacturer of carpet or flooring, is significantly more affordable than current sampling processes, and is user friendly (Tricycle has a dedicated project development team to ensure user-friendliness).

Currently, SIM is improving life for architects and designers in the United States, the United Kingdom and Thailand. The time required for the product selection process can be reduced by as much as 70%. Their job is made easier because samples are color-accurate and easier to use and transport for presentations to their customers. Their resource library footprint has been reduced, a welcome gain as real estate prices climb. Creative options are also opened up, because more options can be evaluated without generating unnecessary waste and manufacturers are not reluctantly producing expensive samples.

In the last year, Tricycle has saved manufacturers more than US $1 million. Manufacturers also benefit because SIM accurately represents their products to customers, and the negative impact of their manufacturing upon the environment is reduced. Instead of dying a minimum 500 pounds of custom color yarn for a sample request, a mill can ship a SIM Strike made with minimal resources. Manufacturers can also use SIM to prototype new product lines, to examine patterns in detail, at full scale, and in virtual environments.

The American environment benefits because the amount of carpet going to landfill is reduced. It is estimated that in the year 2012, even with dramatically improved recycling and reuse efforts, 4.8 billion pounds of carpet will still be going into landfills. SIM can reduce this amount—in the last year alone we diverted more than 20,000 pounds of carpet from landfills.

Future potential? Use of our samples could expand into textile and other surfaces markets, helping to enhance creativity, reduce waste, shorten the creative product lifecycle and keep product prices lower.

Drawbacks of life improvement

The primary drawback is that we have not, to date, been able to find 100% post-consumer recycled paper of the quality and compatibility with our printers. The paper we currently use for SIM prints is 100% recyclable and has a high archival value, reducing the number of prints needed over time. We are working with two printer companies toward using 100% post-consumer recycled paper, produced with no chlorine during the recycling process.

We see no conceptual drawback for the manufacturing industry or its customers.

Research and need

Tricycle’s subsidiary companies first conceived of SIM because of the incredible waste of money, time and environmental resources they saw in the carpet and flooring industry. A large part of how any system should be measured is by its output, and computer aided design software did not output anything that was helpful to architects and designers. Inaccuracies in color and texture were not overcome by the alternative sampling processes that had previously been proposed by manufacturers.

SIM was designed to stand in this gap. It was developed by a team that includes former employees of carpet manufacturers and carpet machine manufacturers, as well as engineers, graphic designers, carpet designers, colorists and more.

Tricycle has also conducted three surveys over the past three years, better to understand the customers of our customers—the architect and interior designer community. We have taken the results of this research and applied it to SIM product development.

Our sales team is also trained to introduce new information gathered from customer meetings back into the research and development loop, so that SIM can be improved according to the flexes of the market.

Designed by

Tricycle, Inc. - United Kingdom