At most airports, luggage is usually handled by two different organizations. Although the airport may own the infrastructure, another company, referred to as the ‘system integrator’, is usually responsible for processing the luggage using their own machinery and IT systems. This lack of synergy often leads to baggage delays, losses, unnecessary effort and sometimes, the use of unsafe methods.

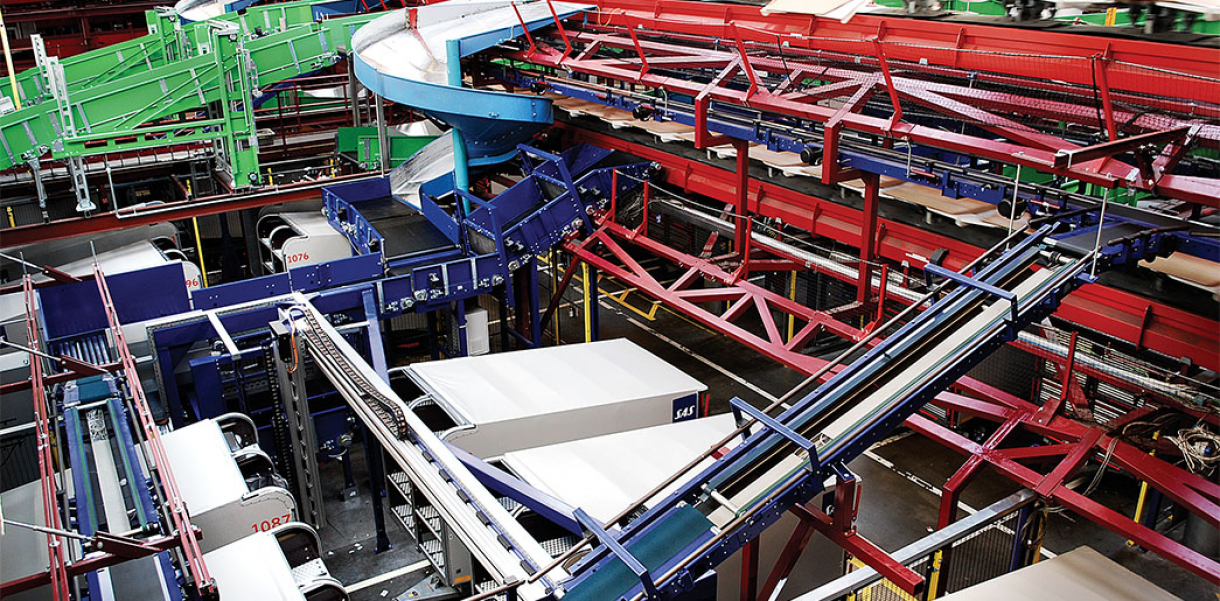

Implemented at Copenhagen airport in 2008, the RampMate® is a luggage sorting and processing system that dramatically improves efficiency and safety. The system brings speed to the entire process and can track luggage anywhere in the airport. Most importantly, whether going in or out of the aircraft, no human lifting is required. The system also includes several built-in benefits including the use of 3B Carts for early storage, increased security and automated sorting of local and transfer luggage.

The project was conceptually developed in collaboration with the ground handler personnel and airport management, with a clear set of interests including minimizing human intervention (no manual lifting); increasing capacity in the sorting hall; increasing efficiency; and tracking/tracing capability throughout the process.

The details of the project were worked out in a collborative effort between SAS Ground Service, CPH Airport, CPH design and Crisplant. Specifically, Crisplant contributed development of the machinery that loads and receives luggage in the sorting hall, integrated with the sorting machine, including high level IT integration. CPH Design developed the mobile linking part including the 3B Aviation Cart.

Designed by

CPH Design - Copenhagen, Denmark.