AÑO

2023

CATEGORÍA

Aprendizaje y Juego

OBJETIVOS

Producción y consumo responsables

PAL. CLAVE

3d printing, recycling plastic, pet plastic

PAÍS

United States of America

CRÉDITOS

Reiten Cheng

LINK

https://www.reiten.design/polyformer

Polyformer

Open-source machine recycling PET bottles into filaments for 3D-printers

How does it work?

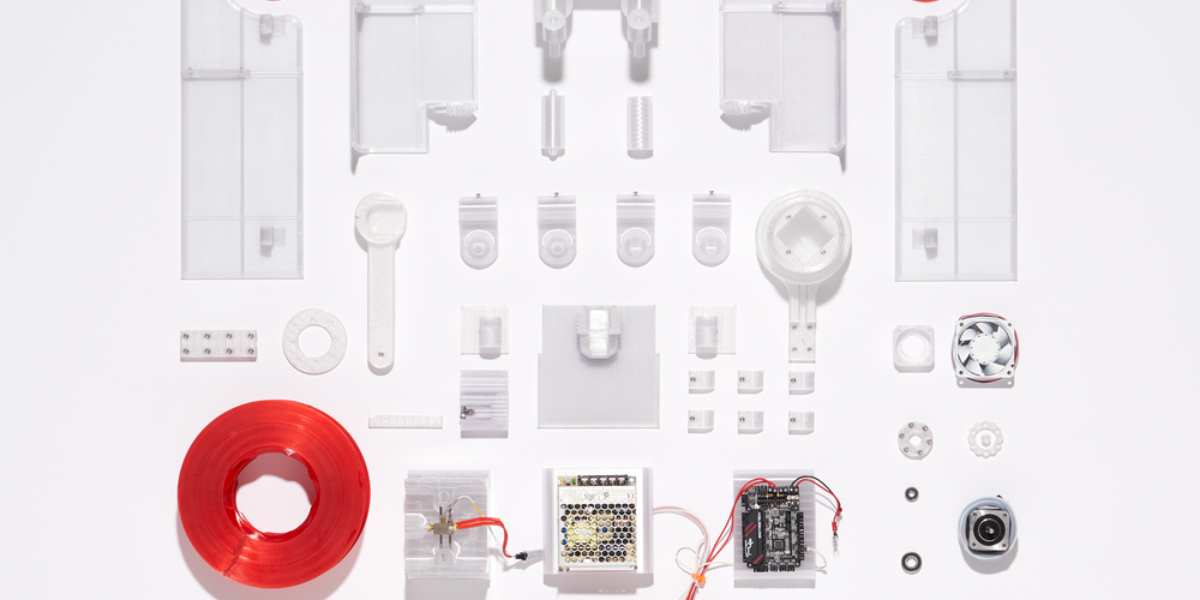

Polyformer is a 3D-printed, open-source machine that recycles PET bottles (90% of plastic water bottles are made from PET) into filaments for 3D printers.

Polyformer in itself is designed to be built with mostly 3D printed parts and/or easily obtainable components commonly found on 3D printers. Most makers can build it themselves. Its modular system allows users to easily swap out parts and modify the machine.

After cutting the water bottle into a long and consistent ribbon, the user can feed the ribbon into the repurposed 3D printer hotend which thermoforms the ribbon into a 1.75mm filament as it goes through the brass nozzle with the corresponding hole size.

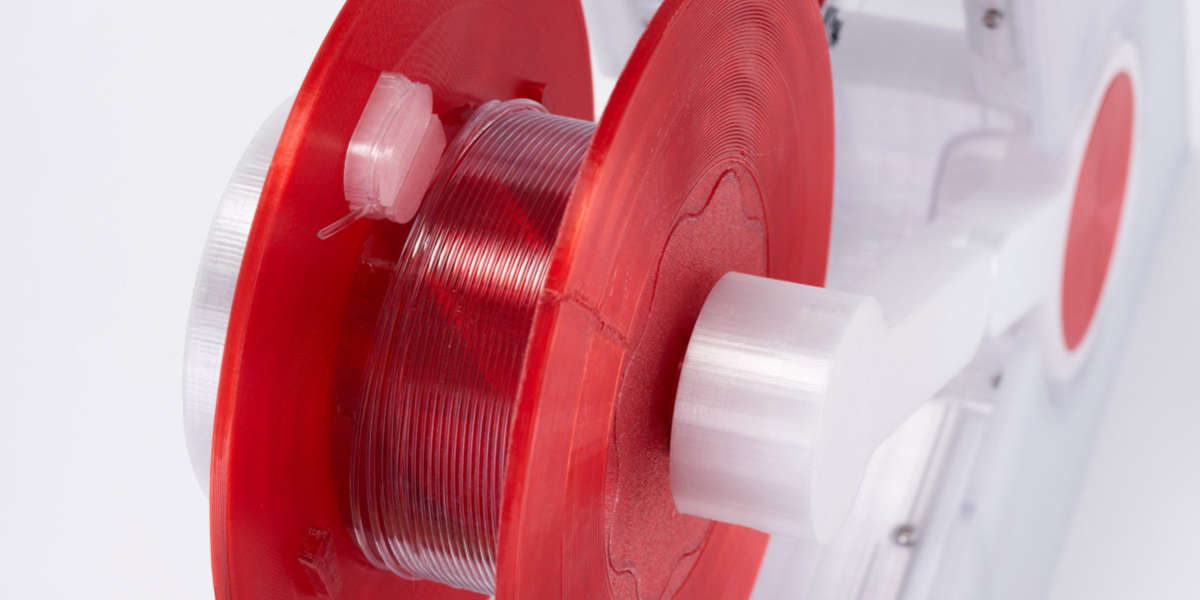

The user can then mount one end of the filament on the red motorised spool to automize the process. The spool can be easily taken off to be transferred and used on a 3D printer.

Why is it needed?

The UN Environment Programme states that of the seven billion tonnes of plastic waste generated globally so far, less than 10 per cent has been recycled. Millions of tonnes of plastic waste are lost to the environment, or sometimes shipped thousands of kilometres to destinations where it is mostly burned or dumped.

Polyformer speaks to a need for more convenient recycling options for the consumer and this machine enables them to also create new products from it.

How does it improve life?

There is a full building guide on GitHub for making the Polyformer.