AÑO

2021

CATEGORÍA

Comunidad

OBJETIVOS

Energía asequible y no contaminante, Producción y consumo responsables

PAL. CLAVE

nuclear energy, nuclear, 3d printing

PAÍS

United States of America

CRÉDITOS

ORNL

LINK

https://www.springwise.com/sustainability-innovation/agriculture-energy/3d-printed-nuclear-reactor-core

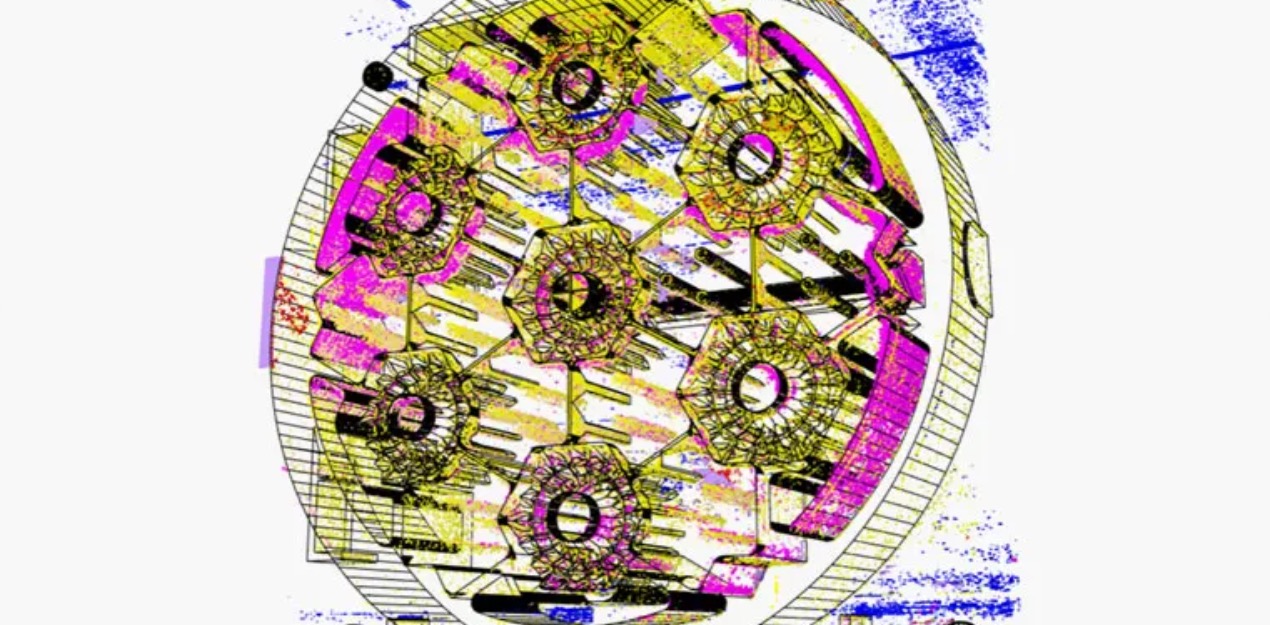

The Transformational Challenge Reactor

3D-printed nuclear reactors

The Transformational Challenge Reactor Demonstration Programme (TCR) at the ORNL has been working on a new approach to reactor design that uses additive technology to rapidly produce reactor cores. The system includes the use of integrated sensors and controls to reduce cost and increase efficiency.

The 3D-printing technology used by the ORNL’s team is not your standard desktop manufacturing process. The process takes around 40 hours to build a hexagonal structure. A laser is used to heat and melt the stainless steel, with temperatures of the melt pool reaching over 1,400 C. Thermal imaging is used to monitor the deposition of the material.

The programme hopes to demonstrate how 3D-printing technology can be used to rapidly innovate in nuclear reactor design and production.