AÑO

2017

CATEGORÍA

Trabajo

OBJETIVOS

Industria, innovación e infraestructura

PAL. CLAVE

D3 printing , metal

PAÍS

United States of America

CRÉDITOS

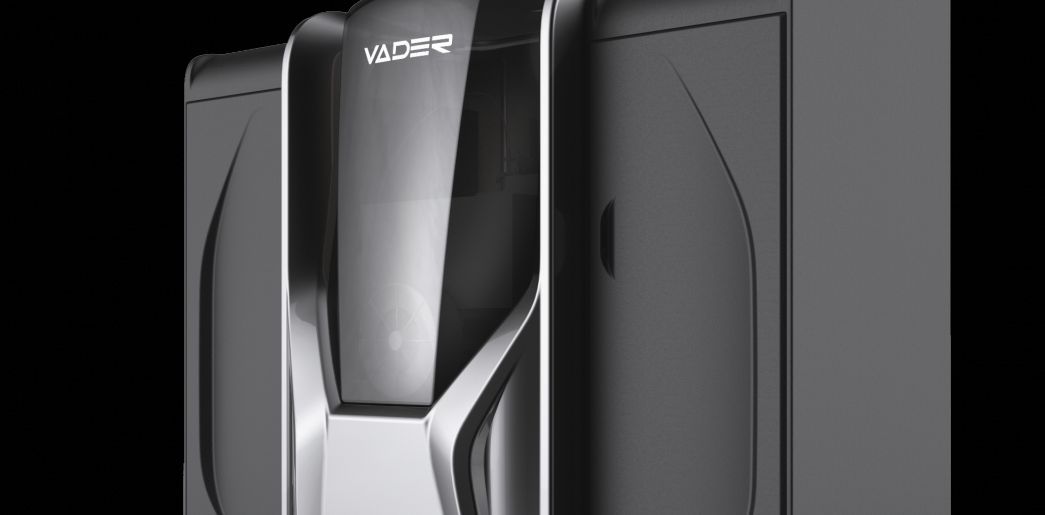

Zack Vader, Scott Vader, Varder systems

LINK

http://www.buffalo.edu/news/releases/2017/01/020.html

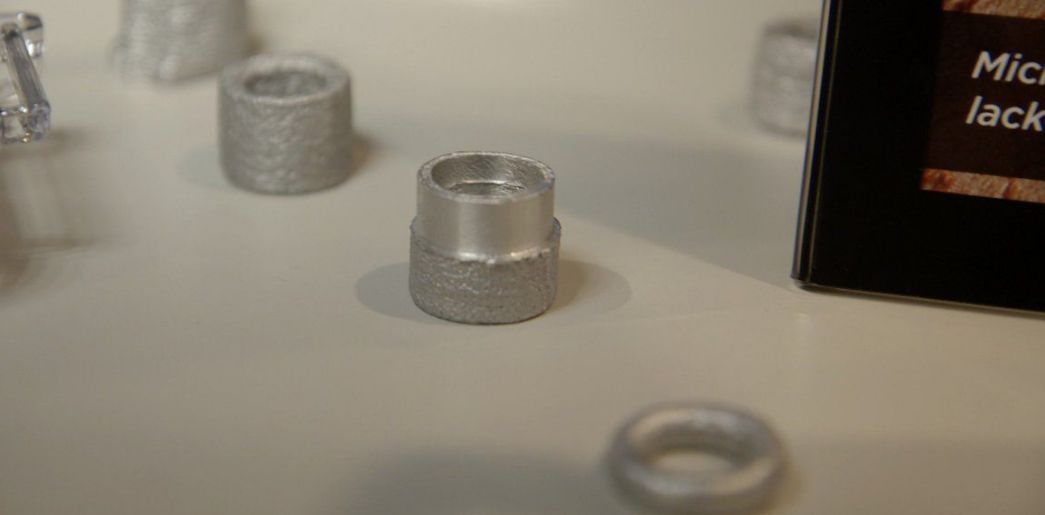

Liquid metal 3-D printing

Liquid metal 3-D printing could revolutionize how things are made made.

The machine is so novel it represents a quantum leap in the ability to print three-dimensional objects in metal. Other metal printers exist, but most use a process of laying down powered metal and melting it with a laser or electron beam. In that process, some particles of the powder do not get melted, creating weakened spots.

Manufacturers are very interested in the Vader machine, with one automotive parts maker expressing an interest in eventually buying at least 50 of them. Professor Edward P. Furlani, PhD, in UB’s Chemical and Biological Engineering and Electrical Engineering departments, said that Vader’s process mimics drop-on-demand inkjet printing and is based on the principles of magnetohydrodynamics, i.e. the manipulation of conductive fluids using a magnetic field. “It’s a transformative technology,” Furlani said. “It’s very exciting interdisciplinary engineering. I think its application base will continue to broaden and expand for the foreseeable future.”