AÑO

2023

CATEGORÍA

Trabajo

OBJETIVOS

Energía asequible y no contaminante

PAL. CLAVE

energy, Green Energy, hydrogen

PAÍS

Israel

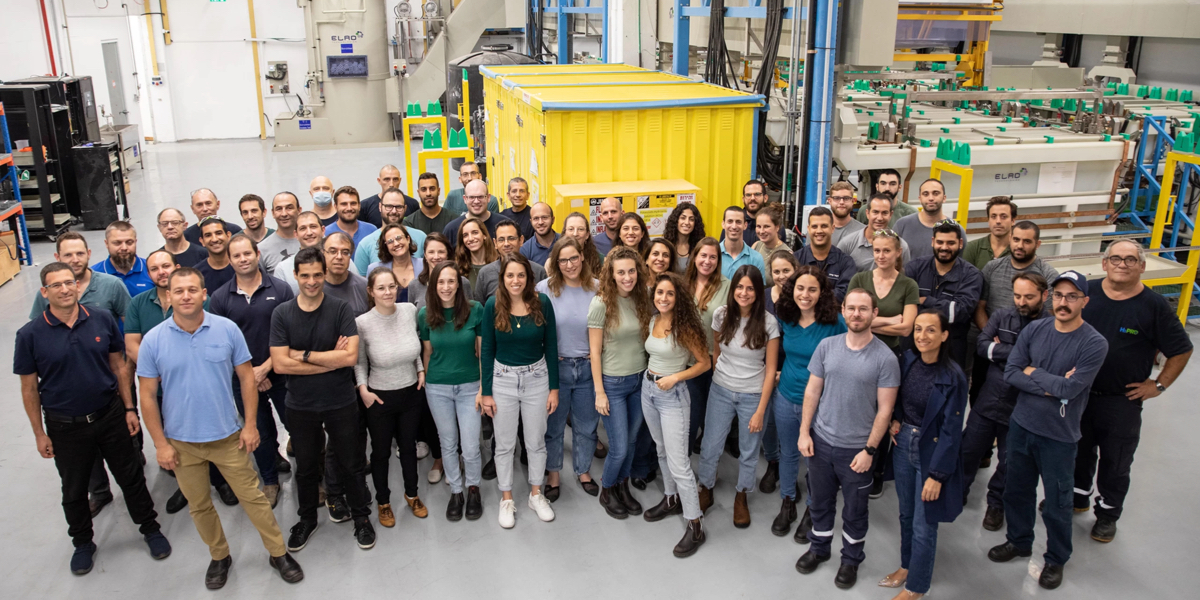

CRÉDITOS

Halo Lor creative

LINK

https://www.h2pro.co

h2pro

Enabling affordable green hydrogen production at scale

How does it work?

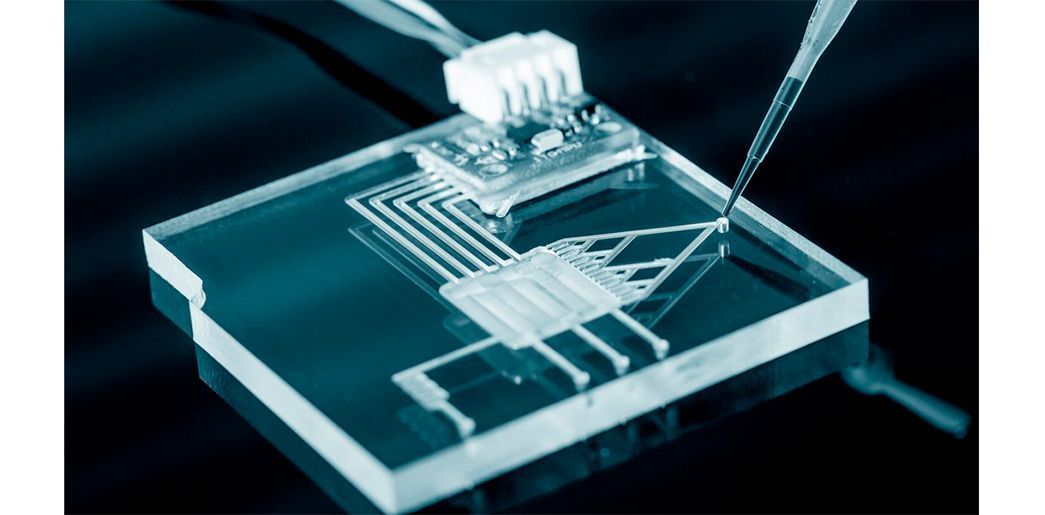

E-TAC is a revolutionary method for producing green hydrogen by splitting water that is over 95% efficient, safe and cost-competitive with fossil-fuel hydrogen.

Why is it needed?

E-TAC water splitting offers the industry’s highest energy efficiency of over 95%, significantly higher than alkaline and PEM water electrolysis with energy efficiency of ~70%.

With hydrogen and oxygen produced at different times eliminating the risk of explosive mixing.

Easy to scale membrane-free technology reduces CAPEX by half compared to traditional electrolyzers.

The membrane-free structure and decoupled H? and O? generation facilitates hydrogen production at 100+ bar without a compressor.

How does it improve life?

Similar to electrolysis, E-TAC uses electricity to split water into hydrogen and oxygen. However, unlike conventional electrolysis, hydrogen and oxygen are generated separately in different steps - an Electrochemical (E) step and a Thermally-Activated Chemical (TAC) step.

E-TAC’s membrane-free electrolytic reactors are suitable for high-pressure hydrogen production and cost-efficient scaling. This disruptive process enables the production of green hydrogen in a way that retains high energy efficiency (98.7%HHV) inside the reactors (see Nature article) and a 95% system efficiency.