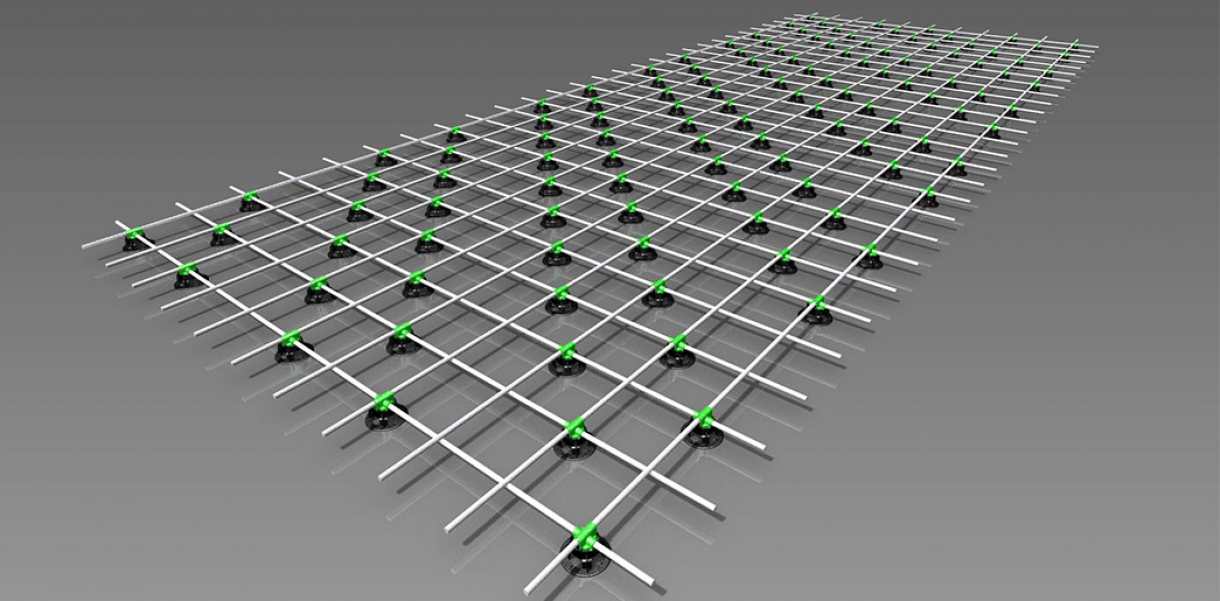

Enviromesh is a simple, light-weight building product that improves current concrete reinforcing practice. Enviromesh is comprised of a recyclable polymer and glass-fiber construction material. It is corrosion resistant and significantly improves the longevity of civil, industrial and residential structures with clear advantages in regards to environmental impact. Enviromesh comes pre-assembled and it can be carried and maneuvered by just one person.

Current concrete reinforcing practice has remained relatively unchanged since its invention in 1849 by Joseph Monier. Steel reinforcing mesh has been the standard concrete reinforcing solution largely because there have been no suitable alternatives. Enviromesh provides the same benefits as steel reinforcing, but removes some of the negative aspects associated with the use of steel.

The manner in which builders use Enviromesh is almost identical to current building practice when using steel reinforcing mesh. The only differences are actually improvements such as the integration of the chairs to the mesh assembly, which means builders are required to do less work during installation. There should be no barriers to full acceptance of the Enviromesh as a highly advantageous alternative to steel reinforcing mesh.

The use of Enviromesh means buildings and structures can last longer, as the materials will not degrade over time. Steel tends to develop ”concrete cancer”, which means that the steel mesh rusts inside the concrete, thus damaging the structure, eventually requiring expensive repairs or replacement. Enviromesh can be used with confidence in the harshest environments, and the extra longevity of structures means less drain on our resources and a significant reduction in the environmental impact of building practice.

Designed by

Glenn Bevan, Adam Doyle and Craig Roughan - Australia