Functionality and use of design

Through the use of heat fins (1) a Peltier cell (2), a heat sink (3) and a base(4), enough electricity is generated (1.8 Watts)(5). If the base is placed in water the efficiency will increase even further.

How did this design improve life?

Harvester Heat is a product that improves the community as well as the individual home in Indonesia. As will be explained further on it creates free electricity and aims to liberate the third world from the IMF and multinational cooperation’s.

Drawbacks of life improvement

As with all products that raise the quality of life, a possible side effect is the envy of neighbours. Also, it will not be patented, so that anyone can make it, competition keeping the project alive. As competition increases manufacturers will be forced to reduce their prices. This can result in compromises being made on the choice of materials, and material thickness, which again can lead to inefficient or even worse, completely defect products.

Research and need

The key to successfully designing a product for the third world is a thorough understanding of local conditions. It is also strongly believed that leaving room for adaptations as the result of unpredictable local circumstances improves the success rate of the project. The research conducted involves the following categories.

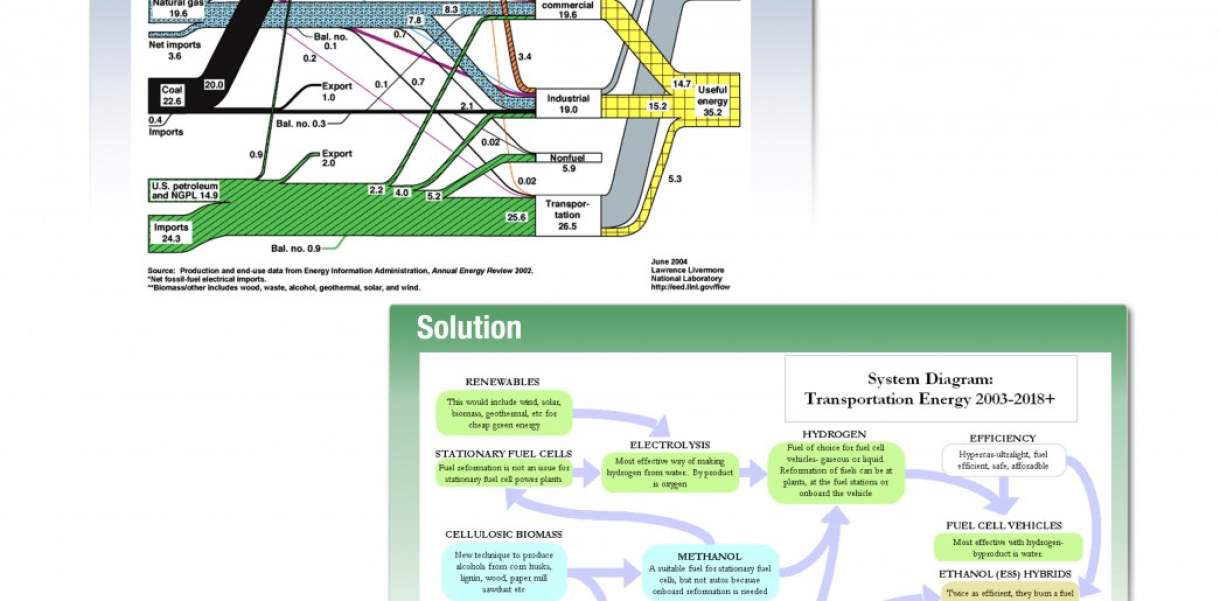

- The need for energy; determining how many people today live without electricity, and how electricity affects a community, and the importance of energy.

- Fuel; going through the different types of fuel, looking at their use, their pros and cons, and how widespread they are.

- Location; determining where this product is needed the most, and focusing on this. For a number of different reasons, Indonesia was chosen as the most suitable.

- Local Conditions; mapping everything from macro-economic conditions to minimum wage, drug problems, social situations, and the influence of international companies and institutions such as the IMF, and World Bank, Nestle and others.

- Similar projects, such as the Kenya Ceramic Jiko oven, have also been scrutinized and their failures or success analyzed.

- The effect of generating electricity on a domestic scale has also been researched.

- Next was prototype development, materials and production research. Eight fully working prototypes were constructed, the final edition being 18000 times more efficient than the first one.

- A chapter was also dedicated to the effect of local adaptations. The Harvester was kept as simple as possible to allow for adjustments as the result of unforeseeable local circumstances.

- Understanding the countries financial, political, and social situation is crucial for implementing an NGO project. The development and testing of the prototype, the environmental impact, packaging and shipping, pricing for EU market, development of instruction manual, and a Failure Mode and Effect Analysis is available on request together with the full research document. The effect of changing the different parts of the product has also been researched as a result of alternative materials being used or other changes. NGOs such as Motivation, Oxfam, and ITDG have shown interest in the project as has workshops in Indonesia. The Logistics has also been calculated making sure shipping, packaging and production is financially plausible. Due to recent events, the project has been put on hold, but the designer is moving to Singapore for three months starting in June 2005 to investigate the possibilities of implementing the project.

Any prize money would go towards implementing the project in real life.

Designed by

Jonas Ravlo Stokke - Norway