AWARD YEAR

2023

CATEGORY

Home

GOALS

Industry, Innovation & Infrastructure

KEYWORDS

aluminium, circular economy, recycled materials, chair, lifecycle

COUNTRY

United Kingdom

DESIGNED BY

Tom Dixon

WEBSITE

https://www.tomdixon.net/en_gb/story/post/hydro/

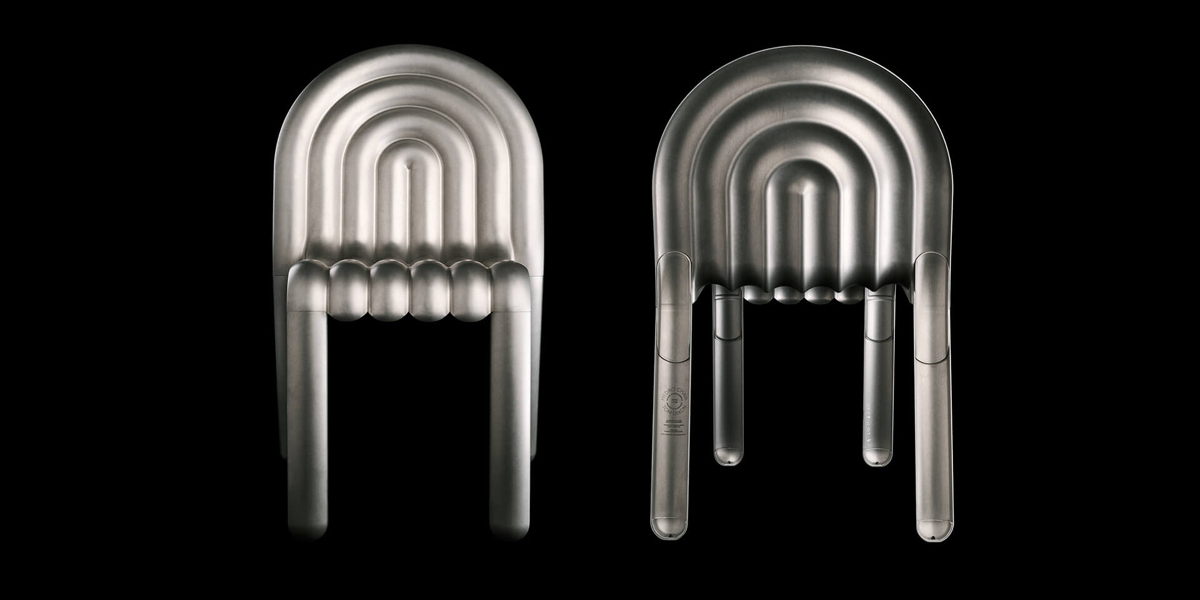

The Hydro Chair

Tom Dixon Studio fashions HYDRO chair with endlessly recyclable aluminium.

How does it work?

Ideal for use both inside and outside, instead of pouring aluminium into molds in liquefied form, or pressed into a solid object, the chair employs a process called ‘superplastic forming’, where molten aluminum is sprayed onto a single mold at high temperatures, and laser cut by robots, peeling off and structuring itself into a definite body.

Similar to how car parts are glued together (not welded, or riveted), the legs are glued to the body with industrial adhesive from the auto industry, as they are made in a Canadian factory that specialises in car body parts mainly for Tesla.

Why is it needed?

British designer Tom Dixon, revered for his instantly iconic designs of furniture, lighting, and accessories, debuts his latest work, the HYDRO chair, in close collaboration with one of the world’s largest aluminium producers, Hydro. The product design's uniqueness lies in its succinct materiality – HYDRO is made from aluminium that can be recycled endlessly without losing its properties (when done right). This, therefore, makes it an ideal material when designing for a circular economy, getting more for less.

“These methods were developed in the automotive industries to make deep and complex forms that were impossible to achieve a few years ago. The ballooned pattern gives strength and rigidity and lends a soft and humorous pop sensibility to the lightweight and shiny metal sheet,” shares Dixon. If its geometry were left flat, the chair would need more metal to sustain itself. The resultant design comes close to just 2.81 kgs,

How does it improve life?

“The future needs circular materials and we need to design products that live longer, can be recycled or reused. Understanding material properties and manufacturing processes will help create more sustainable products designed with recycling or reuse in mind, and that is why we believe it is important for designers and manufacturers to collaborate,” says Hilde Kallevig, Head of Brand and Marketing at Hydro.