AWARD YEAR

2023

CATEGORY

Home

GOALS

Industry, Innovation & Infrastructure, Sustainable Cities & Communities, Climate Action, Life On Land

KEYWORDS

urbanization, city living, sand

COUNTRY

United Kingdom

DESIGNED BY

Alyina Ahmed, Maximo Tettamanzi, Maria Luiza and Elliot Ouchterlony

WEBSITE

https://www.prototypesforhumanity.com/project/ramel/

Ramel

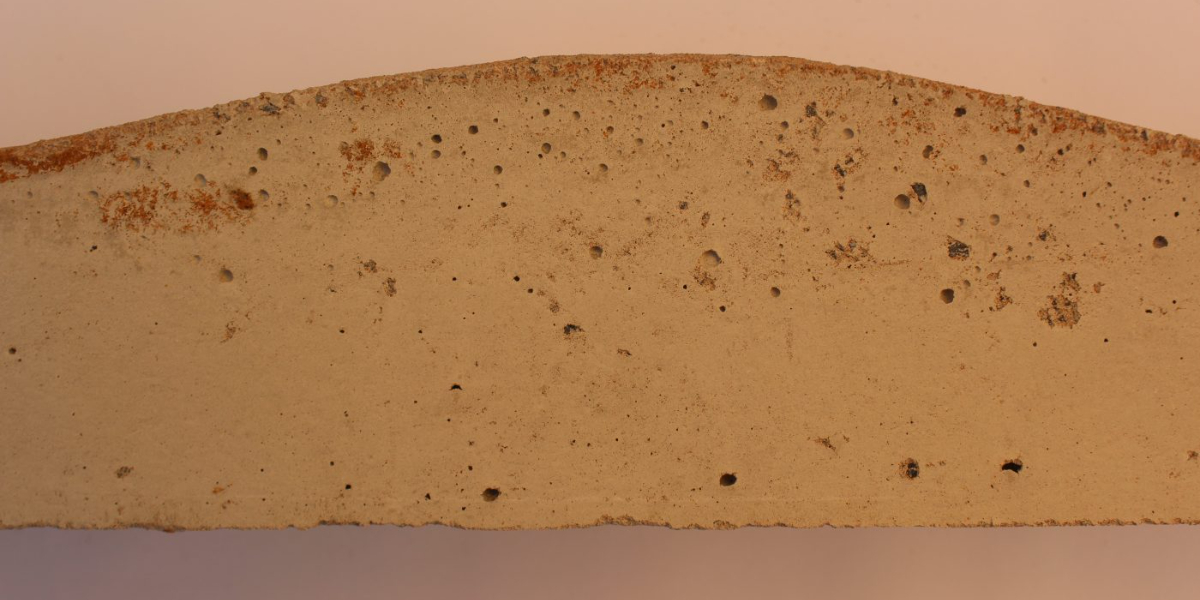

Low carbon and cost-effective desert sand concrete composite

How does it work?

Through research and testing, it is being shown that desert sand, mixed with by-products of industrial processes, can provide a strong alternative to imported sand: initially for use in small-scale projects, and with further testing potentially be applied to larger-scale buildings. As well as being extremely beneficial to the architecture and construction industry, this material could result in a significant reduction in global carbon footprint.

Why is it needed?

The UAE is the 5th largest importer of construction sand in the world, in spite of the fact that it is 80% desert. Construction sand is extracted from mines, riverbeds, or offshore, causing significant environmental damage.

How does it improve life?

Concrete is made of 75% of Sand, 1 mile of highway uses 15,000 Tons of Sand, and our thirst for artificial islands is inextinguishable. Unfortunately, Desert Sand, rounded by the wind, is not suitable for construction or artificial islands and with a growing population & urbanization, our need for Sand is increasing exponentially. Thus, we are quickly depleting our reserve of land or usable marine Sand. Paradoxically, the UAE sitting on the biggest desert, must import Australian Sand for more than 500 MUS$ yearly. At the same time, we face a huge environmental problem as sand extraction from the sea destroys beaches, kills marine life and consumes a lot of fresh water for desalination.

So, Ramel urges to fight an urbanization challenge by substituting riverbed sand with desert sand and concrete with similar cement materials to create a more sustainable composite.