AWARD YEAR

2023

CATEGORY

Community

GOALS

Industry, Innovation & Infrastructure, Responsible Consumption & Production

KEYWORDS

foam, circular, sustainable, zero waste

COUNTRY

Netherlands

DESIGNED BY

moorefoam

WEBSITE

https://www.moorefoam.com/

moorefoam

The world's first and only fully circular and sustainable bio-polyester open cell foam

How does it work?

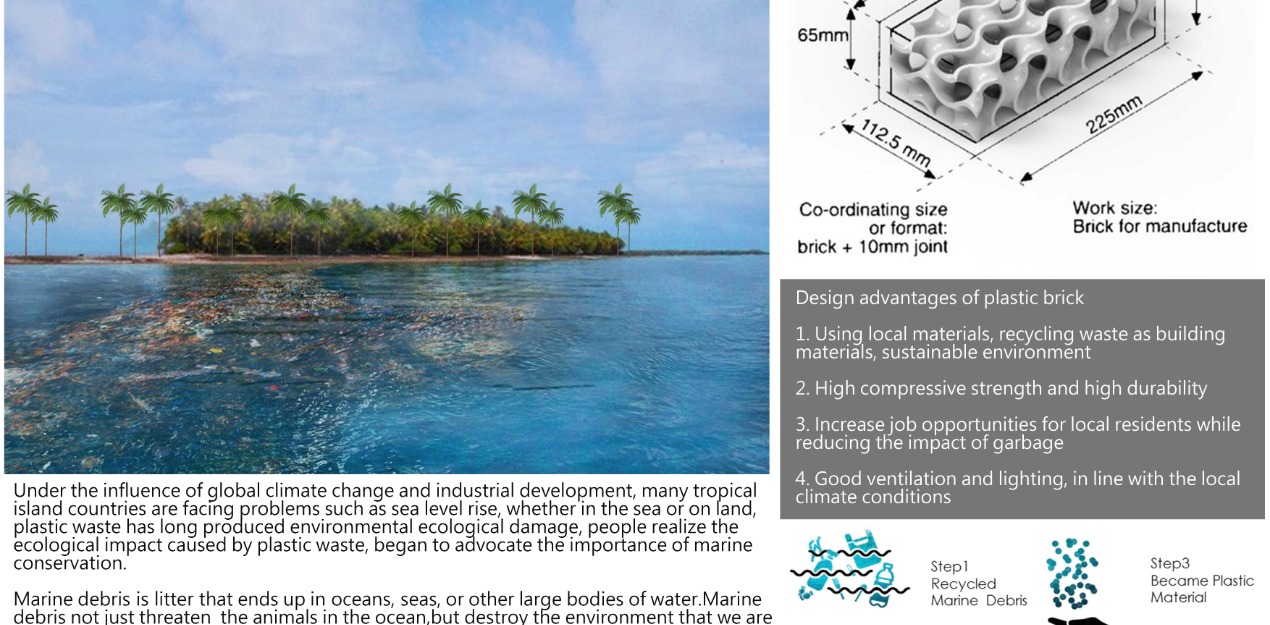

Made from a bio-polyester that can be recycled repeatedly with no degradation to the material, Moorefoam is a quick, easy, and sustainable replacement for any company producing foam-based products. Using a closed-loop production process enables Foamplant to continuously reuse offcuts and waste. Moorefoam is an open-cell bio-polyester which is available in either sheet or flake form, at a variety of sizes. In addition, Bio-polyester is naturally fire retardant, which also allows the company to eliminate harmful chemical treatments from the production process.

Why is it needed?

"Almost 50% of global plastic waste is foam. Every year, millions of m3 of mattress and seating foam are incinerated or sent to landfill, generating unsustainable levels of pollution and raw material waste. Foamplant is launching the sustainable foam alternative the industry urgently needs: moorefoam®.

moorefoam® is the world’s first fully circular open cell foam, enabling bedding, furniture, automotive and avionics manufacturers to make their products sustainable. Through reusing moorefoam®, manufacturers can achieve 90% CO2 reduction. Vastly reducing their operations’ carbon footprint, and achieving their sustainability goals."

How does it improve life?

Foamplant plans to recycle its old products, helping other companies significantly reduce their own carbon emissions – by an estimated 90 per cent according to the company – while also removing millions of cubic metres of waste plastic from the world’s ecosystem. Currently waiting for Series A funding, the company has set a goal of April 2023 for the completion of its first deliveries of the foam.