AWARD YEAR

2023

CATEGORY

Community

GOALS

Affordable & Clean Energy, Industry, Innovation & Infrastructure, Sustainable Cities & Communities

KEYWORDS

hydrogen fuel , Clean hydrogen fuel, seawater , fuel

COUNTRY

United Kingdom

DESIGNED BY

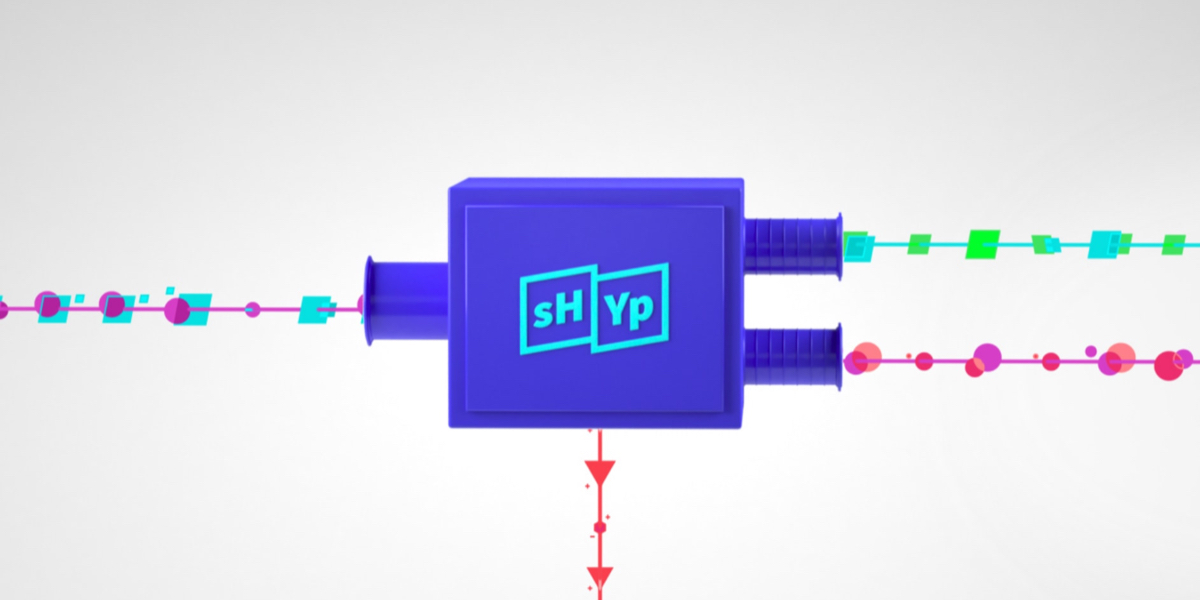

sHYp

WEBSITE

https://shypbv.com

sHYp

Hydrogen from seawater

How does it work?

This revolutionary technology introduces the first electrolyser to use seawater to produce hydrogen. No desalination, no purification, no toxic waste — improvements over existing electrolysis technology to produce the pure water required by existing electrolysers and no toxic waste. A world-first for a greener planet.

A membraneless electrolyser using industry-leading technology splits seawater into hydrogen and oxygen.

Existing electrolysers operate on high purity fresh water which is achieved through purification. If seawater is used, the by-product created from desalination by conventional electrolysis is brine, a toxic salt sludge which is an environmental hazard.

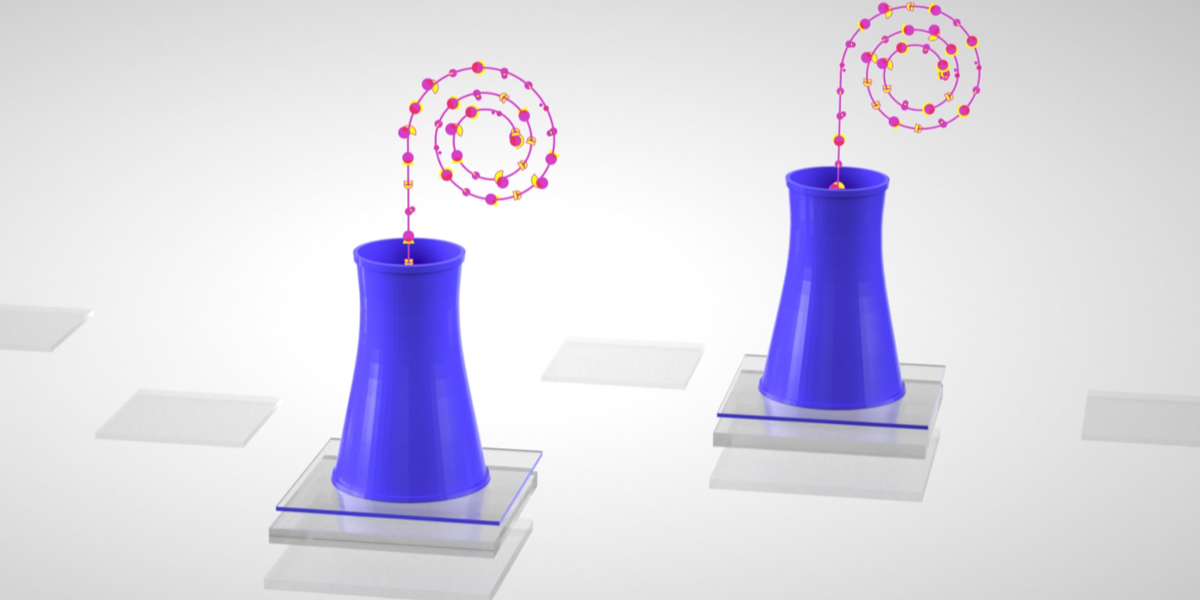

The by-products generated by sHYp’s seawater electrolysis are environmentally friendly and financially valuable. Green hydrogen from sea water.

Why is it needed?

Removing the need for a desalination unit reduces overheads. Environmentally friendly by-products have a range of applications which offset costs. That makes hydrogen green and cheap. It's is an emission-free, clean, cost-effective fuel.

How does it improve life?

sHYp’s electrolysers will have a variety of business applications.

In addition to hydrogen production they can simultaneously be used for magnesium and silica production or CO2 capture, and ballast water treatment.

They can be located in ports, on board vessels and FPSOs and offshore to harness surplus electricity generated by wind, wave and solar.

Ports around the world from Europe to the Middle East to Australia will pilot theirr electrolyser units. Products will be used for a variety of applications, with a focus on shipping and heavy transport.