AWARD YEAR

2023

CATEGORY

Body

GOALS

Good Health & Well-being, Industry, Innovation & Infrastructure

KEYWORDS

Platform, implant production

COUNTRY

Ukraine

DESIGNED BY

WeFund, Kwambio

WEBSITE

https://adambioprinting.com/

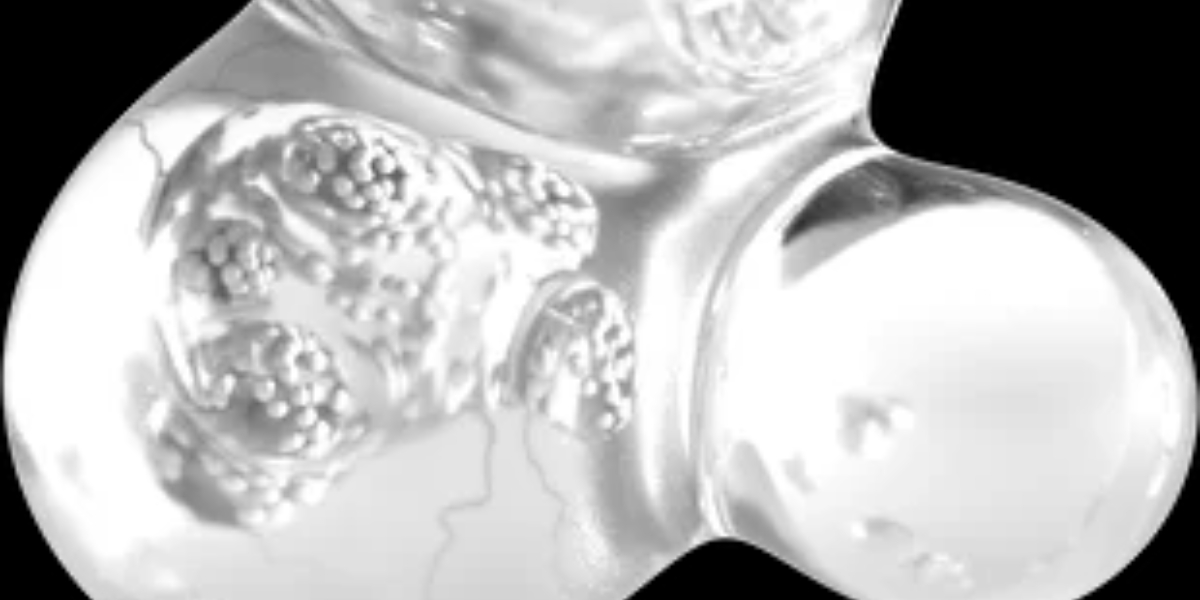

A.D.A.M.

On-demand personalized implant manufacturing infrastructure.

How does it work?

A.D.A.M. is has developed a on-demand personalized implant manufacturing infrastructure with a full scope of related services, provided remotely or on site.

With A.D.A.M., medical professionals will be able to complete all steps of the implant-printing process from 3D-modeling to receiving a sterilized personalized device, ready for implantation.

Why is it needed?

Recently the global healthcare system problems have become strikingly evident. The COVID-19 outbreak has exacerbated existing issues in the industry, causing many professionals to rethink the healthcare models currently in place.

Breakthrough improvements regarding treatment could surely result from big data and AI applications; however, the basic demand for materials (such as human tissue and organs), remains largely unmet due to supply chain vulnerabilities.

How does it improve life?

With the adoption of 3D printing in the healthcare industry, many of these problems could be drastically improved through cost reduction and time saving - effectively supporting a more efficient healthcare system.