AWARD YEAR

2023

CATEGORY

Community

GOALS

Responsible Consumption & Production, Climate Action

KEYWORDS

Bioplastic, mealworms, chitofoam

COUNTRY

United States of America

DESIGNED BY

Charlotte Böhning and Mary Lempres

WEBSITE

https://www.dezeen.com/2022/03/08/doppelganger-chitosan-polystyrene/

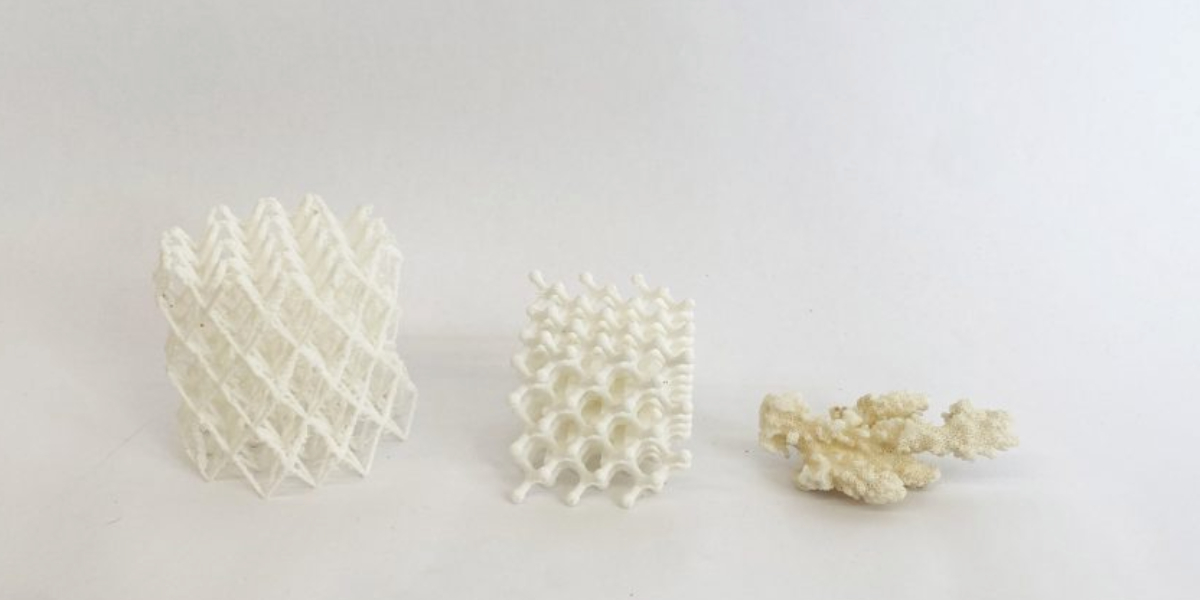

Chitofoam - a bioplastic version of polystyrene

Chitofoam, is shock-absorbent, water-resistant and can be formed into cups and packaging etc.

How does it work?

Doppelgänger (the design studio behind the project) says the bioplastic foam could be made from any mealworm – the larval form of the mealworm beetle – or other insect or crustacean with a chitin-rich shell, such as lobsters and beetles.

"It started off quite simply as a tank with 1,000 mealworms in which we put our waste foam, a material that is unfortunately abundant in design school," Böhning said. "It has gradually grown to include tiered-drawers and many more worms."

"The mealworms can help divert polystyrene waste from landfills and natural environments," she continued. "They can safely and efficiently digest the polystyrene foam with no ill effects on their own health."

With Chitofoam, Doppelgänger aims to show that the little bugs could be used not just to degrade existing polystyrene waste but also to create a bioplastic alternative to it.

As Chitofoam is a thermoplastic it can be melted down and reformed into new products, or placed in soil where it decomposes in 2-3 weeks.

Why is it needed?

Regular EPS, of which Styrofoam is the most well-known brand, is difficult and uneconomical to recycle, meaning it ends up occupying around 30 per cent of the space in our landfills.

"At the end of its short life, polystyrene is not accepted by recycling centres and is undesired by landfills," Lempres told Dezeen. "It is a problematic plastic with no second life that affects future generations, our environment and our future earth."

While polystyrene is made from petroleum-based styrene, which the World Health Organisation has deemed a "probable carcinogen," Chitofoam is derived from a biopolymer called chitin, which mealworms use to build their strong yet pliable exoskeleton.

How does it improve life?

"Mealworm farming has been highlighted in recent years as an environmentally sustainable solution to malnutrition, particularly in developing rural economies," the studio said.

"Growing edible mealworms is affordable, low-resource and space-efficient. The resultant food source is twice as protein-efficient as beef with zero methane emissions."

In this way, the designers say the mealworms could eventually help to tackle two sustainable development goals at the same time, providing food security and fighting pollution.

Early studies have shown that mealworms that have digested polystyrene can still be used to feed other animals, but more research is necessary on whether they could safely be eaten by humans and whether they could be used to break down plastics at a mass scale.

As the mealworms digest the polystyrene, around half of the fossil carbon that was stored in the plastic is also emitted into the atmosphere as CO2, which could contribute to global warming.